About Us

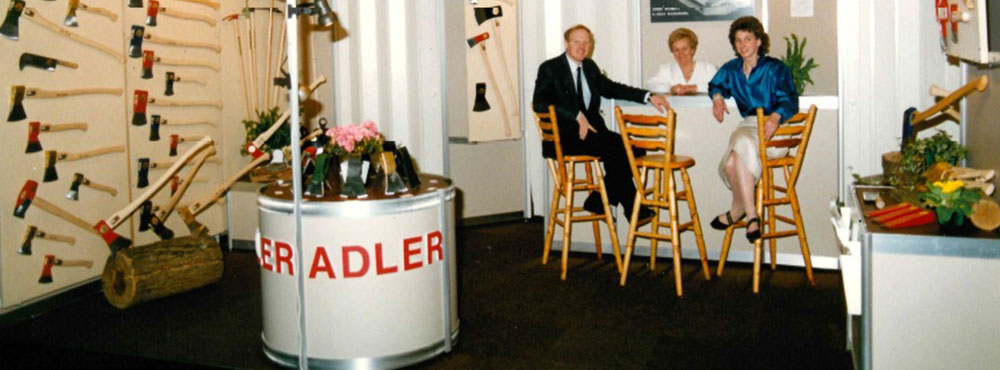

FAMILY BUSINESS IN 4TH GENERATION

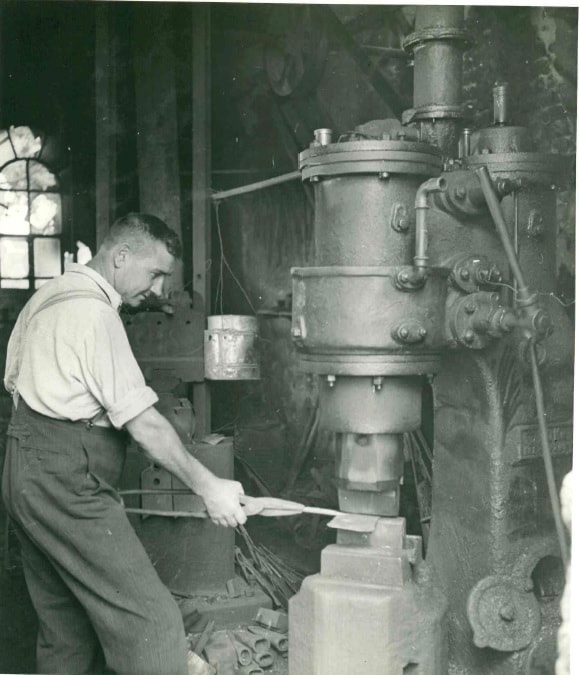

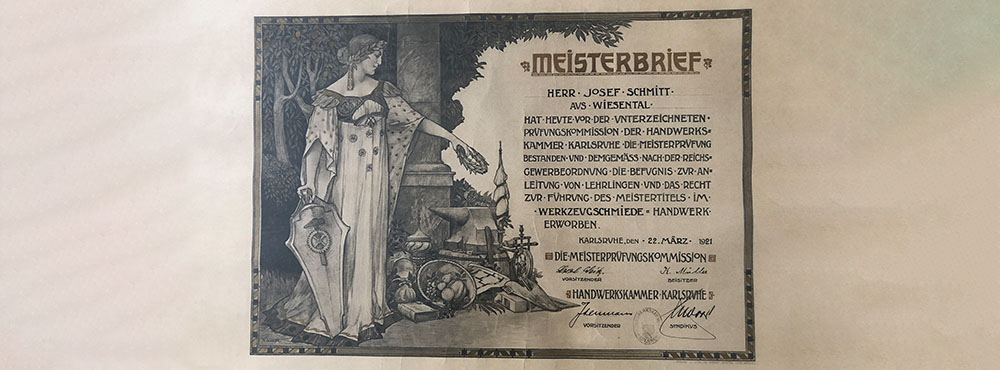

EXPERIENCE SINCE 1919

TOOLS MADE IN GERMANY

Since 1919, our company has been one of the leading specialists in the manufacture of forged forestry and gardening tools as well as high-quality wooden tool handles. Our competence is our production site in Waghäusel, where the knowledge, infrastructure and experience of the entire ADLER team are bundled. From here, we react quickly and flexibly to customer-specific requirements – both nationally and internationally.

Deutsch

Deutsch